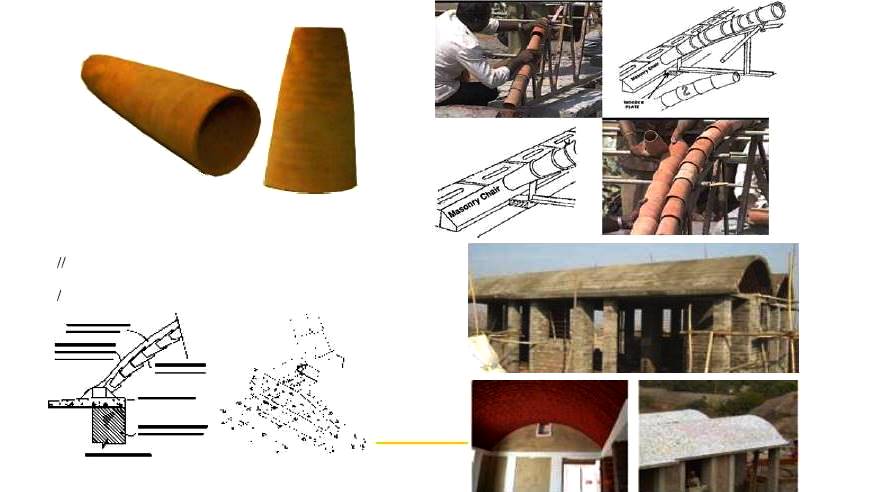

Terracotta Vault Roof Technology

The Terracotta Vault Roof is permanently insulated since it consists of a series of arches made of burnt terracotta conical tile inserted into one another.

The arches are held together by plaster from outside. Fixing of broken china tiles pieces over the roof renders it waterproof and reflects the sunlight making the interior to remain cooler.

Potter making conical tiles laying of conical tile arch roof

The roof needs neither wood nor steel and is most suitable for disaster prone areas like flood & earthquake as it is quick to build, comfortable to live and low in cost.

Appropriateness of Conical Tile Arch Roof

- Cost effective

- Use of locally available material, mud as a basic building material

- Use of energy consuming materials (like metal, steel and cement) is minimized hence these structures are environmentally friendly.

- High labour intensive technology hence generates employment.

- Environmental friendly since the houses feel cooler inside the house in summer in hot in winter season.

- As the mud is main building material, unlike other materials (Concrete and steel), it can be recycled or reused.

The Technology of Mud Wall

The Wall: Ordinary mud (80% murum and 20% BC soil or clayey soil) makes 230 mm thick walls using tile-faced mud blocks 100 mm thick. The masonry joints are filled with cement pointing. The mud block wall is rainproof and rodent-proof. It is worth noting that there is no need to press ram or concrete or add any other binding material to these blocks.

The mud blocks are made using 230 mm X 230 mm wood or steel mold in which facing tile is kept on one side and then filled with mud mixed by hand. If required, the inner surface of the wall can also be tiled. For internal walls mud blocks of 300 X 230 thick are made without face tiles.

All these materials are locally available and the villagers can make the blocks themselves. For a villager house of 250 sq ft, only three days of labor is required for block making. Each block costs very little money.

The face tile is made of burnt clay measuring 230 X 100 X 12mm with a 25mm key. One man can make 250 tiles per day, which can be baked locally by a village potter.

The flooring is IPS (Indian Patent Stone) finished in grey cement colour. Alternatively, flooring can also be, mud or terracotta tile or stone tile, finished.

Door & Window frames are fabricated in mild steel, with horizontal guard bars and fixed in position by hold-fasts to the brick columns. All door shutters and window shutters are in M.S. sheets, or all doors are in ply block board.

Passive cooling of Concrete Flat Roof

Wardha summers with constant power cut makes life under a concrete flat roof a veritable hell. CSV is conducting experiments with Guna tiles to bring down the inside temperature with the help of a forced draught. The chimney pipe upright in the sun on the south side generates a convections current including a continuous flow of fresh cool are entering the Guna row-laid flat on the slab from the opposite side. Temperatures are reported to slide down by about 10-15o than the outside temperature.

Country roofing tiles with lock

CSV improved upon the traditional country roofing tiles by introducing an interlocking system into its design ensuring positional stability, reducing the weight of tiles and making them leak proof. The reduced tile weight reduces the cost of under structure as no wood is required in it.

- Reduced Monetary & Energy Cost

- Reduced Forest Withdrawals

Overlapping wall tiles

A specially designed tile with overlapping corners which eliminate the need for cement pointing. Design of the Tiles Face mud blocks was also modified to fill up the spaces between the tiles.

pointing. Design of the Tiles Face mud blocks was also modified to fill up the spaces between the tiles.

Both sides tile faces wall for Public Buildings

Although protection from the Elements (with terra-cotta skin on the exterior face only) is enough for home walls, public buildings require protection on both sides, to avoid the unnecessary frequent maintenance. It requires an additional cost of only 20%.

Reducing the component of Black Cotton Soil

To minimize the use of fertile Black Cotton Soil (a top quality agricultural soil) in the making of mud blocks, the 30:70 ratio of the B.C. Soil with murum was brought down to 15:80. Murum being stony in character does not suffer from contraction and expansion as B.C. Soil. These murum blocks are more stable.

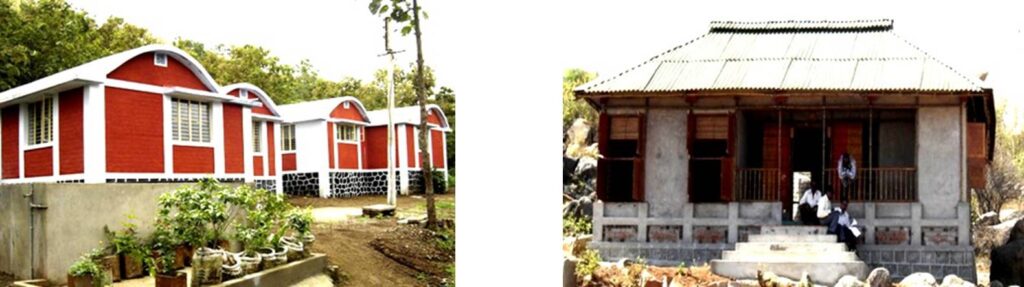

Replication of Technology

- CSV is a building Centre of HUDCO, New Delhi and its housing design (i.e. “Wardha House Model”) is approved by HUDCO, New Delhi.

- ‘Wardha House’ is selected by the Ministry of Rural Development, Government of India for its large scale dissemination through Indira Aawas Yojana (IAY).

Major Extension Activities

- After successfully optimizing the construction technology from 1987 onwards CSV constructed more than 5000 houses in Gujrat, Karnataka, Andhra Pradesh, Madhya Pradesh, Tamilnadu, Kerala, Chhattisgarh, U.P. and Maharashtra, and also outside the country in Ukraine (Russia).

- “Nai Roshani for Moda Village Gujarat by Navy and Naval Wives Welfare Association”

After the earthquake in Gujarat, a completely ravaged village Moda was rebuilt entirely with 155 Houses, School Buildings, a Shopping complex, a community House, Roads, Plantation, and Rainwater Harvesting structures. This project was implemented with the financial aid of the Indian Navy. The project was awarded by the State, Indian Navy, and HUDCO.

- Rural Technology Park

Projects with National Institution for Rural Development (NIRD):

- Mud House with conical arch in the Rural Technology Park at NIRD, Hyderabad (AP).

- Bamboo house in the Rural Technology Park at NIRD, Hyderabad (AP).

- Housing Park

Eight model houses with above technology were constructed at Housing Park at Madhya Pradesh Housing Board, Bhopal.

- Model Houses

Eight Model Houses (Octate)at Butibori near Nagpur for CIDCO, Maharashtra.

- Hostels

Hostels having capacity of 100 students were constructed at:

- SEWA (AIM)

- Pondichery (Tamilnadu)

- /Kodlur (Tamilnadu)

- Polur (Tamilnadu)

- Thiruannamalai (Tamilnadu)

- Kadappa (Tamilnadu)

- Vishakapatnam (Andhra Pradesh)

- Vikrampur, Jabalpur (Madhya Pradesh)

- Masod Dist. Nagpur (Maharashtra)

- Rajgurunagar (two hostels), Dist. Pune (Maharashtra)

- Ashram for Tapasya Trust

Ashram for Tapasya Trust was constructed at Thiruannamalai (Tamilnadu)

- District Primary Education Programme (DPEP):

Gat Sadhana Kendra constructed at AurangabadUsmanabadin Maharashtra for DPEP.

- Indira Awas Yojana

Construction of 400 houses in 16 villages under the Indira Awas Yojana

- Kolhapur District

- YeotmalDistrict

- Nashik District

- Wardha District

- School Buildings

Primary school buildings were constructed in

seven villages of Wardha block:

- Sevagram

- Varud

- Kharangana Gode

- Pipari Meghe

- Tiroda

- Karanji bhoge

- Dairy Farm

Two dairy farm buildings were constructed at Nanded & Akola districts (Maharashtra).

- Rehabilitation of Tribal village

CSV Constructed 40 houses in a tribal village in Vagdhara village, Arvi Block, Wardha district. These houses were constructed under the rehabilitation programme, in collaboration withthe Central Reserve Police Force (CRPF), Nagpur.

- India Song Project

Under the INDIA SONG PROJECT, in collaboration with Wardha Development Association, France, an ideal village with 29 houses was constructed. In each of the

house appropriate technologies like – solid waste, liquid waste management, kitchen gardening, Electricity generation with biogas, Agrowaste chulha, and water filter were installed.

- Eco -Tourism Centre

Constructed 12 units of Eco-Tourism Center for Forest Department, Ministry of Forest,Government of India, at the the following locations:

- Pench Tiger Project, Nagpur, Maharashtra

- Bor Reserve Forest, Wardha, Maharashtra

- Tippeshwar Reserve Forest, Yeotmal, Maharashtra

- Tadoba Andhari Tiger Project, Chandrapur, Maharashtra

<

- Farm Houses

A nunber ofindividual & institutional farm houses were constructed in U.P., Orissa, Jharkhand, A.P., New Delhi and Maharashtra.

- Eco Tech Village

Conceptualized, designed, and implemented a special project entitled, “Eco-Tech Village” under the rehabilitation program at Hingoli District. About 102 houses along with a community hall, Bal Sanskar Kendra, and five shops were constructed with all eco-friendly facilities. The project was funded by the Ministry of Rural Development, Government of India.

- School building

School building for Krishnamurti Foundation Chennai, India

Workshops

- International workshop on Alternative Technologies in “Building Construction”, for Architects and Engineers of South East Asian Countries (June 1998)

- National workshop on Alternative Technologies in “Building Construction”, under MGNAREGA for Ministry of Rural Development, Govt. of India, at CSV during 2nd and 3rd May 2014

Training

A range of training programs on low-cost Building Construction were organized at Wardha Building Centre located in the Kumarappapuram campus of the institute. Some of the major programs carried out by CSV are listed below.

CAPART Sponsored Programs

The year 1986 to 1994 CSV Conducted three-month training programs for Non Governmental organizations of the following nine states of India:

- Tamilnadu

- Kerala

- Karnataka

- Andhra Pradesh

- Orissa

- West Bengal

- Aasam

- Uttar Pradesh

- Bihar

- The year 1997 – 98 conducted training for 30 engineers and architects of South East Asian countries i.e. Bangladesh, Sri Lanka, Pakistan, Nepal, and India for one month supported by UNESCO, India.

- In year 1996 – 1998 trained more than 2,500 masonsfrom different districts of Maharashtra in sanitation structures and technologies.

- In year 2005 – 2008 trained more than 1,100 masons from 11 districts of Vidarbha i.e. Gadchiroli; Chandrapur; Gondia; Bhandara; Nagpur; Wardha; Amravati; Yavatmal; Akola; Washim and Buldhana.

- In year 2014 – 2015 trained 80 students from D. Y. Patil College of Architect, Mumbai

Publications

A book entitled “Building Dreams in Mud” is published in the subject of Building Vault Roof Houses. Documentary: Mud Construction